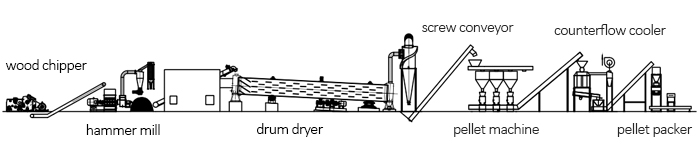

Complete wood pellet plant is used to make biomass materials into wood pellet fuel. The production capacity is from 500kg to 2ton per hour. It is composed of a hammer mill, dryer, conveyor, pellet machine, conterflow cooler, and pellet packing machine, etc.

Complete wood pellet plant is used to make biomass materials into wood pellet fuel. The production capacity is from 500kg to 2ton per hour. It is composed of a hammer mill, dryer, conveyor, pellet machine, conterflow cooler, and pellet packing machine, etc.

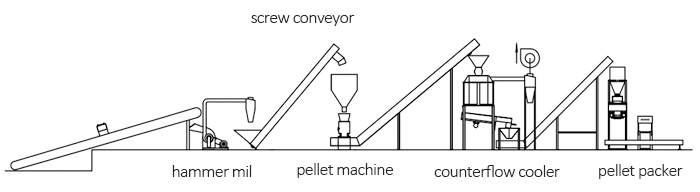

The small wood pellet production line can accomplish the whole process of wood pellet production, including raw materials crushing, drying, pelletizing, pellet cooling and packing. It applies to various biomass materials such as sawdust, wood chips, wood shaving, crop straw, stalk, rice husk, wheat bran, peanut husk, grass, alfalfa, hay, etc.

The core part of small pellet plant is the flat die pellet machines. The production capacity of one pellet machine is 200-800kg/h, and you can combine several sets to achieve higher capacity. We can offer solutions of 500kg/h,1t/h, 2t/h, etc. They are suitable for small or medium scale factory, farm and new comers of biomass industry. Small wood pellet plant takes up less space. They are easier to install and maintain, and the cost is lower than large pellet plant who adopts ring die pellet machine for pelletizing.