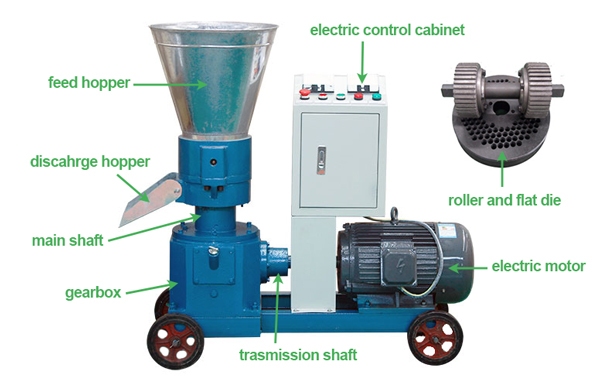

Electric pellet machine 150 is a small-size, mobile flat die pellet machine. It is driven by a 3-phase electric motor. The power ranges from 5.5kw to 22kw. The production capacity is from 50-100kg/h to 250-400kg/h. It is equipped with 4 wheels that enable you move it to anywhere easily. Different from electric pellet machine 150-300C, this type has the electric motor half covered. This design contributes to thermal dissipation, and save the production cost. So this is a portable and economical type for home use and small-scale production.

Pellet machine is used to make high-density wood pellets with sawdust, straw, rice husk, barks and other biomass materials. As a green and renewable energy, wood pellets are used in home heating, central heating, industrial boiler and electric generator. The application of wood pellets can save energy and reduce air pollution. It has become an important energy source in developed countries.

This mobile pellet machine is composed of a electric motor, a gearbox, a transmission shaft and a main shaft, a flat die, a roller, a feed hopper, a slicer, a discharge hopper, and a electric control cabinet, etc.

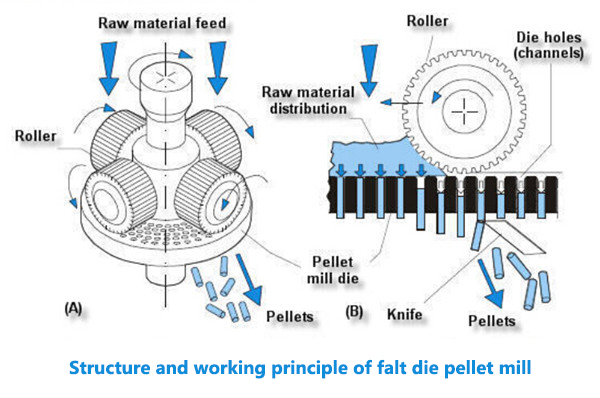

When you power on the pellet machine, the electric motor drive the main shaft through the gearbox and transmission shaft. The flat die connected with the main shaft start to rotate. The roller shaft keep still while the 2 rollers rotate around it.

When the biomass materials are fed into the hopper, they fall on the flat die. During the rotation of the flat die, the rollers roll across the raw material layer and press them into the holes on flat die. The biomass materials are formed into cylindrical pellets in the holes. When they come out under the flat die, there is a slicer cutting them off. At last, the biomass pellets fall on the pellet-throwing disc and get out though the discharge hopper.

The raw materials for making wood pellets include sawdust, wood chips, crop straw, corncob, rice husk, cotton stalk, cotton seed hull, peanut shell, grass, branch, bark, household garbage, factory waste, etc. Besides, pellet mills can be used to make pellets from biological fertilizer, organic fertilizer, compound fertilizer, etc.

To make wood pellets, the moisture content of raw materials should be 10%-18%. If your materials don’t meet the requirement, you need to dry them with natural air or a dryer machine.

The maximum size of raw materials should be less than the hole size of flat die. Usually the flat die hole size is 6mm and 8mm, and the diameter of the materials is 3-5mm. If you materials don’t meet the requirement, you can crush them into fine sawdust with a wood chipper or hammer mill.

You can use single biomass materials to make wood pellets, or mix several materials together. For example, rice husk has less adhesive force, so it is usually mixed with sawdust to make pellets. But make sure there is no iron or stones in the raw materials or they may damage the pellet mill.

The pellet mill can achieve good pelletizing effect with no need for any binders. But to improve the production, extend the service life of flat die and roller, we recommend you to add binders if needed.

Small household feed pelletizer, also known as pellet feed machine and pellet feed molding machine, belongs to feed pelletizing equipment. It is a kind of feed processing machine that directly presses the granule with the comminuted matter of corn, soybean meal, straw, grass and rice husk. It is widely used in large, medium and small aquaculture, food and feed processing plants, livestock farms, poultry farms, individual farmers and small and medium-sized farms, farmers or large, medium and small feed processing plants. Model from 125-400.Feel free contact us.

Diesel engine rotating roller flat die pellet making machine is a self-developed equipment specialized in making biomass pellet fuel. It adopts diesel engine as drive, and rotating roller and stationary die as pelletizing device. This series of diesel pellet making machines covers 3 types, 200A,300A and 400A, whose capacity is from 80-450 kg/h. They are suitable for small and middle scale production, as a cost-effective choice for small business users.Feel free contact us.

Gasoline engine pellet making machine is not as popular as electric motor type, but it’s a suitable choice for people who have easier access to gasoline. TICO provide biomass pellet making machine with different drive engines to adapt to various demand. The pellet production is from 90 to 120kg per hour. And the gasoline engine turns up 13 horsepower.