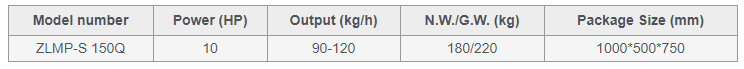

Gasoline engine pellet making machine is not as popular as electric motor type, but it’s a suitable choice for people who have easier access to gasoline. TICO provide biomass pellet making machine with different drive engines to adapt to various demand. The pellet production is from 90 to 120kg per hour. And the gasoline engine turns up 13 horsepower.

Gasoline engine pellet making machine is not as popular as electric motor type, but it’s a suitable choice for people who have easier access to gasoline. We provide biomass pellet making machine with different drive engines to adapt to various demand. The pellet production is from 90 to 120kg per hour. And the gasoline engine turns up 13 horsepower.

Our gasoline pellet making machine adopts rotating flat die and stationary roller as pelletizing system. They are made of heat-treated superior alloy steel, who have 3-4 times the lifespan of those in other pellet making machines. It features stable transmission, low noise, high bearing capacity and low temperature.

Further more, this pellet making machine is directly driven by gasoline engine through gear transmission, which has avoid the slippery of belt drive. All drive assemblies are contained in an gearbox filled with oil. The surface of gearbox has been nicely grinded, processed by carburizing and quenching treatment. Enhanced by stiffeners, the machine enclosure is able to sustain high pressure.

As a specialized biomass equipment, it applies to various biomass materials, including agriculture residues, household garbage, and factory waste. Besides, it is able to process those with low bonding ratio and difficult to compress. You don’t have to add and binders to them. Moreover, it is capable of producing organic fertilizer and compounded fertilizer at low temperature.

These biomass pellets are environmental friendly fuel, which has small volume and high combustion ratio, with little carbon emission. Nowadays, they are widely applied in pellet stove for home heating and cooking, industrial boiler and power plant.

Whenever you want to make biomass pellet with this machine, remember to warm it up with oil mixture( fully mixed 3-5kg raw materials and 10% oil) for around 5 minutes. The gasoline pellet making machine will work more smoothly if the temperature is up to 80-100℃.

Small household feed pelletizer, also known as pellet feed machine and pellet feed molding machine, belongs to feed pelletizing equipment. It is a kind of feed processing machine that directly presses the granule with the comminuted matter of corn, soybean meal, straw, grass and rice husk. It is widely used in large, medium and small aquaculture, food and feed processing plants, livestock farms, poultry farms, individual farmers and small and medium-sized farms, farmers or large, medium and small feed processing plants. Model from 125-400.Feel free contact us.

Electric pellet machine 150 is a small-size, mobile flat die pellet machine. It is driven by a 3-phase electric motor. The power ranges from 5.5kw to 22kw. The production capacity is from 50-100kg/h to 250-400kg/h. It is equipped with 4 wheels that enable you move it to anywhere easily. Different from electric pellet machine 150-300C, this type has the electric motor half covered. This design contributes to thermal dissipation, and save the production cost. So this is a portable and economical type for home use and small-scale production.

Diesel engine rotating roller flat die pellet making machine is a self-developed equipment specialized in making biomass pellet fuel. It adopts diesel engine as drive, and rotating roller and stationary die as pelletizing device. This series of diesel pellet making machines covers 3 types, 200A,300A and 400A, whose capacity is from 80-450 kg/h. They are suitable for small and middle scale production, as a cost-effective choice for small business users.Feel free contact us.